Advanced technologies are swiftly transforming various facets of our lives, and one such domain is the electronics industry. Thanks to unprecedented innovations such as the invention of the transistor, clean rooms, and photolithography, the production of electronic components has reached unparalleled heights.

Cutting-edge methods now facilitate the creation of increasingly compact and high-performance chips for smartphones, computers, and other gadgets we use daily. It all started from the early electronic tubes and primitive circuits and now continues with modern nanoscale processors with billions of transistors.Â

Much of this progress would have been impossible without Apple, a leading force in innovation within the field of electronic devices. Each year, the company astonishes with revolutionary gadgets that set new standards for the entire industry. Let’s delve into how the methods of electronic component manufacturing have evolved and the role played by the Cupertino giant, especially in providing cutting-edge parts for Apple devices.

Development History

The first radio tubes, triodes, and sets of radio components for assembling receivers in the early 20th century were primarily produced manually due to small production volumes. With the advent of assembly lines and the shift to mass production of radio technology, the pace significantly increased. For instance, by the 1930s, RCA’s assembly line could produce more than 15,000 radio tubes per day!

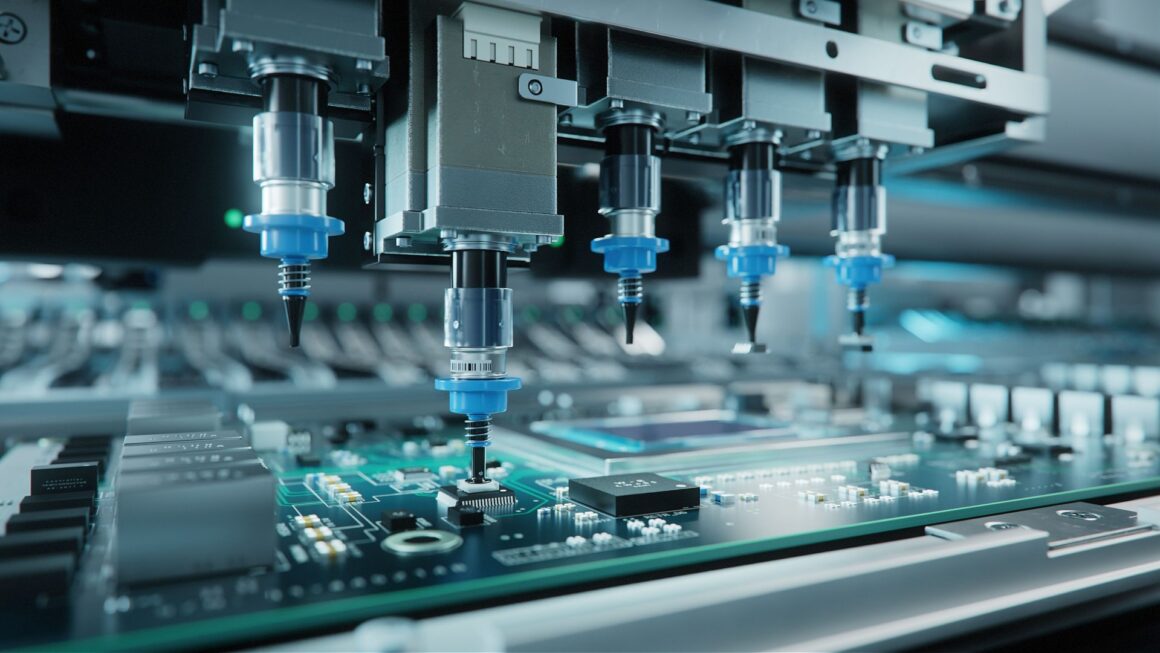

Simultaneously, efforts were made to automate individual operations using special machines, robots, and measuring instruments. This increased assembly accuracy and speed. In the 1970s and 1980s, there was a trend toward comprehensive automation, where all production stages were performed and monitored by robotics.

A significant leap occurred in the 1990s and 2000s with the transition to nanotechnology. It became possible to manufacture chips and processors with transistors of nanometer sizes, sharply increasing element density and computational power.

In addition to refining manufacturing processes, there were developments in new materials, such as silicon on insulators, GaN, and graphene, with improved characteristics for creating more efficient and economical components.

Apple’s Contribution

Apple played a key role in driving progress in manufacturing technologies in the electronics industry. For example, the first iPhone in 2007, with its touch-screen sensor, forced competitors to completely reconsider their approach to smartphones. The 2010 iPad essentially created a new category of tablets. To produce such innovative devices, Apple motivated its component suppliers to continuously improve production.

Developing increasingly compact and high-performance devices like the iPhone and iPad each year, Apple encouraged its component suppliers, such as TSMC, Samsung, and LG, to continuously modernize their production. To meet Apple’s requirements, these companies had to implement the most advanced manufacturing processes at an accelerated pace. For instance, the chips in the iPhone 7 lineup, released in 2016, were produced using 10 nm standards, while many other chip manufacturers were only transitioning to 14 nm processes.

What’s more, Apple invested hundreds of millions of dollars in researching promising technologies and materials, such as MEMS, organic light-emitting diode displays, high-capacity lithium-polymer batteries, and much more.

As noted by leading analysts at Digitimes, these developments spread throughout the industry, stimulating the production of more sophisticated electronic devices. According to them, Apple is effectively the “engine of progress” for the entire electronics market.

Many experts predict the emergence of revolutionary technologies that will fundamentally reshape the landscape of electronics manufacturing in the coming decades. Specifically, the widespread adoption of 3D printing for creating integrated circuits and other electronic components is anticipated. This is expected to significantly reduce costs and expedite the production of small batches of complex products.

Active developments are underway in the field of flexible electronics based on organic semiconductors and nanomaterials. Flexible displays, sensors, and solar panels have the potential to radically transform the design of gadgets. There are high expectations for neuromorphic processors, which simulate the functioning of neural networks in the brain. Their computational power is anticipated to be unparalleled compared to traditional chips.

Modern Trends

Today, automation and robotics have become indispensable elements for survival in the competitive environment of the electronics industry. Industry leaders such as Foxconn, Quanta Computer, and Pegatron are integrating hundreds of thousands of industrial robots from Kuka, ABB, and Fanuc into their production processes. Automated machines not only perform routine operations accurately and swiftly but also optimize the logistics of components within the factory.

Moreover, advanced information technologies are gaining increasing significance in managing complex supply chains in electronics manufacturing. This involves AI-based systems, big data, and the Internet of Things for tracking, analyzing, and optimizing material and component flows:

- Gadgets are equipped with various sensors, tags, and chips that transmit data about their location, condition, and other parameters.

- Specialized software processes this vast amount of information, providing recommendations to reduce costs, prevent failures, and address “bottlenecks”.

Such “smart” logistics systems enable companies to respond more quickly to demand, optimize inventory, and increase production capacities. Market leaders like Apple actively implement such solutions in collaboration with suppliers, becoming a crucial competitive advantage in the battle for consumers.

Another characteristic feature is the use of “smart factories” equipped with numerous sensors, machine vision systems, and feedback loops. Artificial intelligence analyzes extensive data at each stage of production for the maximum optimization of all processes, considering various product models. These flexible production lines make it easy to scale output according to demand.

Yet another trend is the establishment of a distributed network of factories worldwide, including outsourcing to countries with low labor costs. This helps reduce expenses and ensure the production of a vast quantity of electronics for the entire planet.

Conclusion

Over the past decades, the production of electronic components has undergone a colossal transformation, from the manual assembly of early radio tubes to highly automated nanotechnology-driven factories today. Industry leaders like Apple have significantly contributed to this progress with their innovations and investments in new developments. Even in the current challenging economic conditions, further technological revolutions can be expected at this dynamically evolving intersection of science, technology, and business.